Buying Guide

Choosing the Right Forklift for Your Needs

Forklifts serve as versatile industrial vehicles employed for lifting and transporting materials, proving indispensable across various sectors such as manufacturing, warehousing, various process industries, and construction. When contemplating the acquisition of a forklift, it is crucial to select the most suitable one to meet your specific requirements.

8 Factors to Consider When Buying a Forklift

Capacity

The primary consideration is the capacity of the forklift, indicating the maximum weight it can safely lift. It is essential to assess the heaviest loads you will handle and the available space. Additionally, factors affecting lifting capacity include:

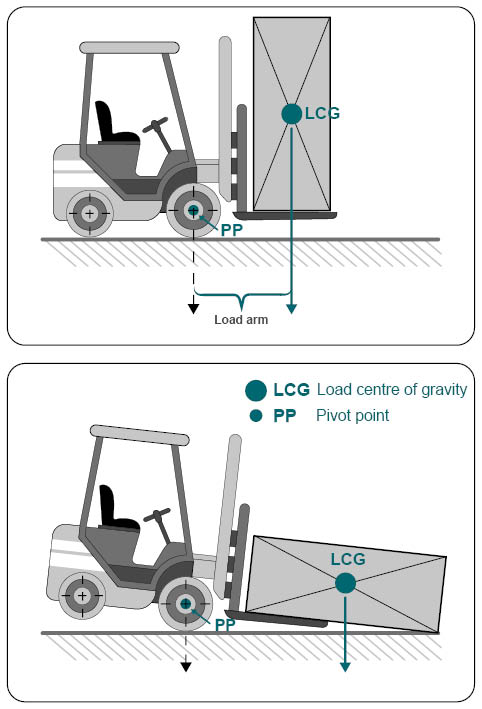

- Load center – The further the load center is from the pivot point of the forklift, the lifting capacity decreases.

- Lifting height – With increased mast height, the lifting capacity decreases.

- Attachments – Additional attachments, such as side shifters, block clamps, bale clamps or paper roll clamps, derate the forklift’s lifting capacity.

Lift Height

The lift height refers to the maximum height the forklift can raise a load. It is essential to factor in the heights of your shelves, racks, and loading/unloading trucks. Forklifts offer various lifting masts, allowing you to select the appropriate mast that suits your maximum lifting height requirement. Additionally, it is vital to consider the minimum collapsed height of the mast, as this indicates if the forklift can operate under mezzanines, enter low doors, or work inside ISO containers.

Power Source

Forklifts operate using either electric or internal combustion (IC) engines. Electric forklifts offer quieter operation and are more environmentally friendly than IC forklifts, but they have a shorter range. In regions like the Middle East, where ambient temperatures and humidity levels are high, the longevity of batteries and electrical components may deteriorate. On the other hand, IC forklifts are more powerful and have a longer range, but they emit emissions.

Tire Type

The choice of tire for your forklift depends on the driving surface. Cushion tires are ideal for smooth surfaces, while pneumatic tires are more suitable for rough terrain. While cushion tires are puncture-proof, they can lead to increased fuel consumption and a bumpy ride on uneven surfaces, potentially hastening the depreciation of the forklift.

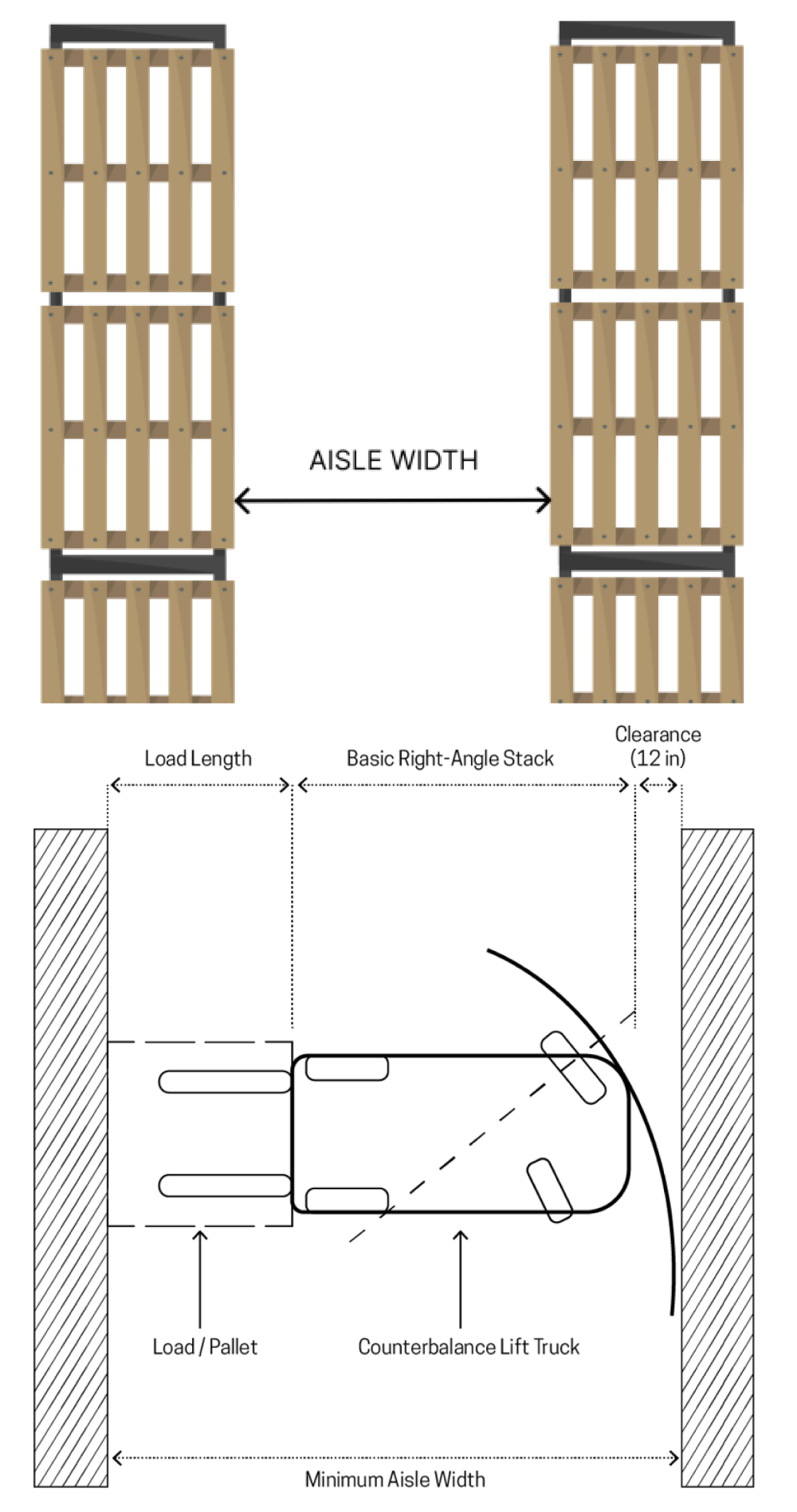

Right Angle Stacking Aisle Width

Right Angle Stacking Width is the minimum distance between two consecutive aisles required for a forklift to turn and enter a pallet. This can be determined using the following:

Minimum Aisle Width = Right angle stack + Load length + Clearance (12 inches)

A narrower aisle width in a warehouse can lead to more efficient warehousing and potential cost savings. However, it may require the purchase of a more expensive forklift to operate smoothly within the confined space. The following types of forklifts are listed in descending order of their aisle widths:

- Diesel or Gasoline Forklifts

- Electric 4-wheel Forklifts

- Electric 3-wheel Forklifts

- Electric Reach Trucks

- Articulated Forklifts

- Very Narrow Aisle (VNA) Units

Operator Comfort

Operator comfort is essential for ensuring safety and productivity. One must ensure that the forklift is equipped with a comfortable seat, excellent visibility, and user-friendly controls. Features such as suspension seats, cabins, vertical exhaust, effective engine dampening, and noise cancellation contribute significantly to enhancing operator comfort.

Slopes or gradients in your warehouse

This aspect can often be a decisive factor when choosing the right forklift for your warehouse. Typically, both diesel and electric forklifts can handle a maximum gradient of 1:20 (vertical lift to horizontal stretch ratio) in laden conditions. However, electric three-wheel configuration forklifts with rear-wheel drive have significantly lower gradient capabilities compared to similar four-wheel configuration forklifts.

Cost

There are two costs associated with a forklift. Firstly, there is the purchase price, with electric forklifts typically being more expensive to buy than diesel ones. Secondly, there are repair and maintenance costs to consider. While used forklifts may initially seem more affordable, the expenses and challenges related to frequent breakdowns and repairs can make them less appealing in terms of overall value-for-money.

Types of Forklifts

Forklifts are most commonly classified into the following three categories:

Counterbalance Forklifts

These are the most common type of forklifts, characterized by a counterweight at the back that balances the weight of the load.

Electric Reach

Trucks

These forklifts are specifically designed for narrow aisles, boasting a long reach that enables them to pick up and put away loads without the need for turning.

Rough Terrain

Forklifts

These forklifts are tailored for rough terrain applications, featuring large tires and high clearance to navigate uneven surfaces effectively.

In conclusion, making an informed decision ensures optimal performance, safety, and efficiency in your operations. We hope this guide has provided valuable insights to assist you in making the best choice for your needs. For further assistance and personalized advice, feel free to reach out to our experienced sales engineers. We are here to help you find the perfect forklift solution tailored to your specific requirements.

WANT GET IN TOUCH WITH AN EXPERT?

Can’t wait for a callback? Call us now on +971 6 531 9779